Havanna gas cylinder management with RFID in Cuba

Gas cylinder management (ca. 1,2 Mio. gas bottles) with RFID in Havanna, Cuba

The project challenges didn't seem to that difficult at the beginning, but there were certain particularities that had to be taken into account.

The project requested a seamless monitoring of gas cylinder at different areas with different tasks. Either with mobile devices or fix mounted reader.

General information for the filling station

- The management of the maintenance cycles of gas cylinders

- The sorting of the gas cylinders that have reached their lifetime

- The average filling cycle of a gas cylinder

General information for the distribution stations

- The customer-related cylinder distribution

- The average consumption per customer

- The general need for gas cylinders

With regard to the technical requirements, the specification of the intrinsic protection of the devices (ATEX) also came into play for the filling station.

Technical equipment filling station

- ATEX Zone 1 transponder LF

- Fix Reader LF and antennas with ATEX Zone 1 certification

- PDA with LF reader with ATEX Zone 1 certification

Due to technical requirements, the following devices were used at the distribution stations.

Technical equipment distribution stations

- PDA with GPRS, BT, Wifi and LF Reader

Fix Reader LF and antennas connected to the PDA (loading and unloading process of trucks).

Transponder (tags)

Here were selected tags that allow a selective reading of the gas cylinder. At the same time, the reading distance had to be at least 30 cm. The tag MUST be stuck to the bottle to eliminate all manipulation. Should he be knocked off, however, he had to be destroyed.

Furthermore, the same tag type had to be fixed to all transport trucks (in a steel housing) so that they could be welded to the lower edge of the loading area.

Last but not least, the tag had to be ATEX Zone 1 certified.

Here, the choice fell on a LF EM4200 glass transponder. This fulfills both all technical and commercial criteria.

Rugged PDA

In particular, attention was paid to the robustness of the PDA, as they are used daily in a harsh environment. Another important factor was the display, which can be operated simply with the finger and is easy to read even in direct sunlight.

Furthermore, it was important that the device brings all the communication possibilities (WWAN, WLAN and BT) in order to map the special requirements in different applications.

Lastly, it had to be a PDA that is easy to fix. Spare parts supply and technical training are part of the armament for a long-lasting use.

Another important requirement was that the device could run on both Windows Mobile and Android.

Here the choice fell on the device of handheld Nautix X8 with the LF reader developed by AGILLOX for the X8.

Autonomous Fix Reader with wireless communication to the PDA

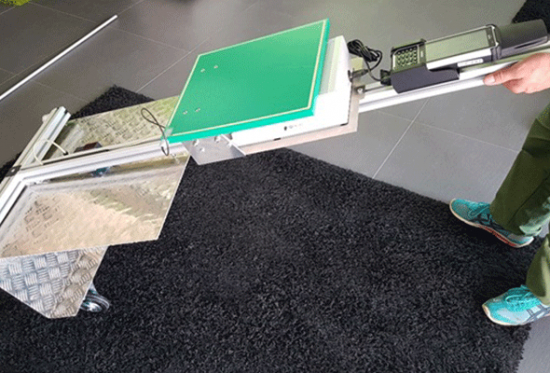

This product did not exist with the desired options and specifications in the market. Without further ado, a fix reader with these criteria was developed. The reader is used for fast loading and unloading of the gas cylinder truck. Here, the cylinders must be brought quickly from and to the truck.

The procedure should be done without affecting the handling of the cylinders. At the same time, the cylinders had to be registered by RFID and the data had to be forwarded to the PDA. In addition, it was important that the worker receives feedback as to whether the cylinder has been safely registered (visual and audible signal at each reading).

Another criterion was that the cylinder is only read when it passes the station. Last but not least, the station should be operating completely without external power connection (battery) and ensure a working time of approx. 8 hours.

The following functions were included:

- Mobile version (rollable)

- A foldable antenna

- Autonomous function without external power supply (battery for 8 hours runtime)

- A sensor to ensure bottle presence

- BT data transmission

- Power connection to possibly operate PDA in parallel

- Holder for PDA

- Light weight and rugged.

AGX-AMGBS100 (ready for transportation)

AGX-AMGBS100 (in operation connected to the X8)

With this solution AGX-AMGBS100 it is possible for the first time to carry out the loading and unloading of trucks in the shortest possible time. This mobile and autonomous technical configuration allows every truck to be equipped with it.

It is unloaded and ready in less than 1 minute. Gas cylinders (no matter what content), beverage containers, beer kegs, wine barrels or other goods can be processed quickly hereby.

Direct communication with the PDA thus allows online data to be sent, for example, to a cloud application.

The 21,000 mAh battery effortlessly supports an operating time of continuous 8 - 9 hours. This can cover a complete working day.

If necessary that you can also charge the battery while driving from one location to another via the on-board network of the truck.

Both the AGX-AMGBS100 and the Nautix X8 can be connected to any SW product, allowing complete flexibility even for existing solutions. The communication possibilities of the PDA (WWAN, WLAN and BT) allow a location-independent functionality and thus a unique M2M solution.

In Havana, communication via WLAN was chosen first because the 3G infrastructure does not yet exist seamlessly. However, this will take place in the near future via WWAN (3G).

AGILLOX has developed a tailor-made solution according to the wishes and requirements of the customer, which today has no equal.

The next two other regions in Cuba have already expressed their interest in the same solution. We are looking forward to it.

A great project in a charming country.

Your AGILLOX team